Fashion and elegance

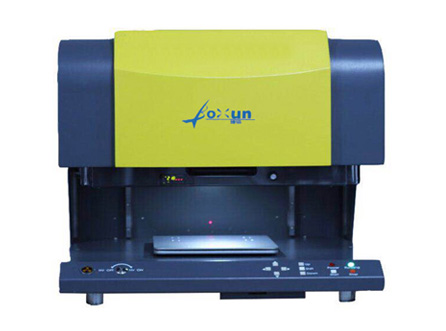

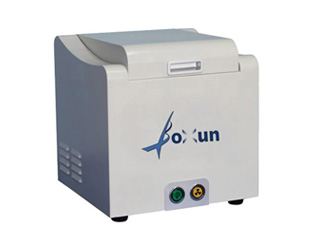

Streamline design is selected for the appearance of the instrument

Bxr-626 series X-ray fluorescence coating thickness gauge adopts X-ray fluorescence analysis technology, which can measure the thickness of various metal coatings, including single-layer, double-layer, multi-layer and alloy coatings, and can measure the composition concentration of electroplating solution.

It can detect the thickness of common metal coatings without sample pretreatment; the analysis time is short, only tens of seconds; the dynamic range of analysis and measurement is wide, from 0.005 μ m to 60 μ M.

Streamline design is selected for the appearance of the instrument

From sulfur (s) to uranium (U) in the periodic table

It can analyze 5 layers of coating and 24 kinds of elements at one time

No complex sample pretreatment process is required

The detection limit can reach 2ppm

Wide dynamic range from 0.005 μ m to 60 μ M

Advanced detector, high energy resolution

Using advanced amp, the processing speed is fast and the precision is high

The X-ray tube is excited by positive high pressure, and the excitation and test conditions are controlled and displayed by computer software

The color camera is used to observe and shoot the sample accurately

The x-y-z movement can be carried out by using the electrodeless control sample platform

Double laser focusing system is used to locate the measuring position accurately

Height sensor

Protect the sensor, effectively protect the detector

Low failure rate

Multi layer shielding protection of concealed design, software and hardware triple radiation protection system

| X-Y-Z sample platform mobile device | The x-y-z sample platform of bxr-626 series X-ray fluorescence coating thickness gauge adopts an electric mobile device and has a large sample chamber which can accommodate various shapes of coating samples and electroplating liquid samples. It is easy to use |

| X-ray tube excitation system | The excitation system is designed with orthorhombic optical structure. High voltage generator: the voltage and current are automatically controlled and displayed by software. The maximum power is 50 W. Voltage 0-50 kV, current 0-1000 UA. 8 hours stability ≤ 0.05%. Long life X-ray tube: the X-ray tube with low power, natural cooling, high life and advanced level is adopted, and the index reaches the advanced level. The maximum power is 50W, the pipe pressure is 5-50kv, and the pipe current is 0-1000ua |

| High resolution detector system | Imported original electric refrigeration detector, good energy linearity, energy resolution and spectral characteristics, high peak to back ratio. The best resolution is 149ev ± 5ev |

| Electronic system of energy spectrometer | Original import preamplifier and amplifier signal processor: adapt to high count rate, high anti-interference ability of integrated electronic circuit. The analog-to-digital converter adopts 2048 channels with high precision |

| Computer analysis system | Brand computer; high resolution color LCD. Ink jet printer |

| Systems software | XRF analysis software, including empirical coefficient method, basic parameter method (FP method), theoretical α coefficient method and other classical analysis methods, fully ensures the accuracy of single layer, double layer, multi-layer, alloy coating test data |

| Power Supply | AC 220V~240V、50Hz 。 Rated power: 120W. Selection of high precision parameter regulated power supply |

Industrial coatings of plastic products, coatings of electronic materials (connectors, semiconductors, circuit boards, capacitors, etc.), coatings of iron and steel materials (iron, cast iron, stainless steel, low alloy, surface treated steel plate, etc.), coatings of non-ferrous metal materials (copper alloy, aluminum alloy, lead alloy, zinc alloy, magnesium alloy, titanium alloy, precious metal, etc.) Thickness measurement and composition analysis of other coatings.

Gc-ms3200 gas chromatography m...

Gc-ms3200 gas chromatography m...

Gc-ms3200 gas chromatography m...

Gc-ms3200 gas chromatography m...

Gc-ms3200 gas chromatography m...

Fax:0512-66326763-801

E-mail:cheng@boxunyq.com

Website:http://www.ojvr.cn

Add:39 wangmi street, high tech Zone, Suzhou City, Jiangsu Province